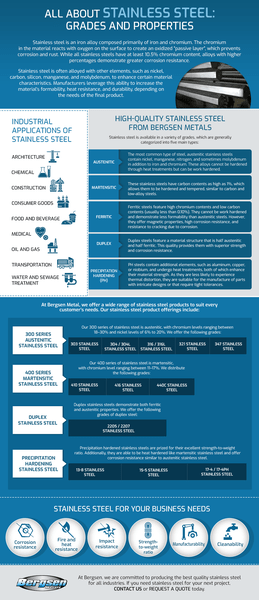

Stainless Steel Grades and Properties

Stainless steel is an iron alloy composed primarily of iron and chromium. The chromium in the material reacts with oxygen on the surface to create an oxidized “passive layer”, which prevents corrosion and rust. While all stainless steels have at least 10.5% chromium content, alloys with higher percentages demonstrate greater corrosion resistance.

Stainless steel is often alloyed with other elements, such as nickel, carbon, silicon, manganese, and molybdenum, to enhance certain material characteristics. Manufacturers leverage this ability to increase the material’s formability, heat resistance, and durability, depending on the needs of the final product.

Industrial Applications of Stainless Steel

Stainless steel finds application in a wide range of industries, including:

Architecture

As stainless steel is highly durable and impervious to rust, it is frequently used for a variety of architectural components, including cladding, handrails, fittings for doors and windows, street furniture, rebar, lighting fixtures, and masonry supports. It is also valued in architectural design for its aesthetic appearance.

Chemical

Stainless steel is prized in the chemical industry for its tensile strength and chemical resistance. It is often used for process pipes and pressurized containers.

Construction

Stainless steel is found in a number of construction parts and products due to its high durability and corrosion resistance. Construction materials made with stainless steel include mechanical springs, fasteners, and wires.

Consumer Goods

Stainless steel’s corrosion resistance makes it especially useful for household items that are frequently exposed to water. The material is used for the manufacture of a variety of common household goods, including cutlery, kitchen countertops, sinks and faucets, pots and pans, washing machines, ovens, and refrigerators.

Food and Beverage

The material’s corrosion resistance and easily sterilized surface make it particularly useful for the food and beverage industry, which requires high standards of cleanliness. In this industry, stainless steel is used in food preparation and catering equipment, piping and containers used for brewing and distilling, and a wide range of food processing equipment.

Medical

In the medical industry, stainless steel is highly valued for its chemical and corrosion resistance—which facilitates sterilization—making it popular for use in surgical instruments, medical devices, and implants.

Oil and Gas

Stainless steel’s chemical resistance and durability make it particularly useful in the oil and gas industry, where it is used for tanks, platforms, cable trays, and subsea piping.

Transportation

Stainless steel is rarely used in large quantities for everyday automobiles due to its heavier material weight. However, it can be found in smaller automotive components, such as in exhaust systems and on car trim. Its uses in the transportation industry are typically reserved for heavy-duty equipment, such as tanker trucks, ship containers, chemical tankers, and garbage trucks, used for the transport of bulky or corrosive materials.

Water and Sewage Treatment

Water and sewage treatment facilities find stainless steel especially helpful for water and sewage pipes and tubing and water tanks, due to its rust and chemical resistance.

High-Quality Stainless Steel From Bergsen Metals

Stainless steel is available in a variety of grades, which are generally categorized into five main types:

- Austenitic. The most common type of steel, austenitic stainless steels contain nickel, manganese, nitrogen, and sometimes molybdenum in addition to iron and chromium. These alloys cannot be hardened through heat treatments but can be work hardened.

- Martensitic. These stainless steels have carbon contents as high as 1%, which allows them to be hardened and tempered, similar to carbon and low-alloy steels.

- Ferritic. Ferritic steels feature high chromium contents and low carbon contents (usually less than 0.10%). They cannot be work hardened and demonstrate less formability than austenitic steels. However, they offer magnetic properties, high corrosion resistance, and resistance to cracking due to corrosion.

- Duplex. Duplex steels feature a material structure that is half austenitic and half ferritic. This quality provides them with superior strength and corrosion resistance.

- Precipitation hardening (PH). PH steels contain additional elements, such as aluminum, copper, or niobium, and undergo heat treatments, both of which enhance their material strength. As they are less likely to experience thermal distortion, they are suitable for the manufacture of parts with intricate designs or that require tight tolerances.

At Bergsen Metal, we offer a wide range of stainless steel products to suit every customer’s needs. Our stainless steel product offerings include:

300 Series Austenitic Stainless Steel

Our 300 series of stainless steel is austenitic, with chromium levels ranging between 18–30% and nickel levels of 6% to 20%. We offer the following grades:

303 Stainless Steel

Due to its sulfur and phosphorus content, 303 stainless steel is highly machinable. It is typically used in the aerospace industry for fittings, gears, bolts, and nuts.

304 / 304L Stainless Steel

304 is the most commonly used austenitic stainless steel. 304L is a variation that has a lower carbon content. 304 finds use in a variety of industries, including automotive, food and beverage, nuclear, and shipping, while 304L is generally used in welding applications.

316 / 316L Stainless Steel

Compared to 304, 316 is less commonly used. The alloy contains more molybdenum and nickel and is available in a low carbon variation—316L. Its composition allows for higher corrosion resistance, especially to chlorides such as salt and sea water. 316 is suitable for use in nuclear plants and marine environments, while 316L often finds application in the pharmaceutical and chemical industries.

321 Stainless Steel

Both 321 and 321H contain titanium. However, 321H has a higher carbon content for greater temperature resistance. Both alloys are frequently used in chemical processing and oil and gas refineries.

347 Stainless Steel

347 and 347H contain a higher concentration of niobium and tantalum, making them suitable for welding applications. Both materials can often be found in airplane and automobile components and chemical storage tanks.

400 Series Martensitic Stainless Steel

Our 400 series of stainless steel is martensitic, with chromium level ranging between 11–17%. We distribute the following grades:

410 Stainless Steel

410 is durable and highly resistant to wear but is more susceptible to chemical corrosion and oxidation. The material is often used in automotive parts, medical products, nozzles, pipelines, and valves.

416 Stainless Steel

416 contains sulfur, which allows for greater machinability. This quality makes it suitable for use in a variety of products, including valves, pumps, studs, gears, and washing machine components.

440C Stainless Steel

Due to its high carbon content, 440C is exceptionally hard and wear resistant; however, it is only moderately corrosion resistant. This material is useful for knives, surgical implements, nozzles, bearings, and other items that require that the material retain its shape under pressure.

Duplex Stainless Steel

Duplex stainless steels demonstrate both ferritic and austenitic properties. We offer the following grades of duplex steel:

2205 / 2207 Stainless Steel

2205 and 2207 are widely used grades of duplex stainless steel. Due to their high strength and corrosion resistance, they are often used in components for the marine, chemical, oil, and gas industries.

Precipitation Hardening Stainless Steel

Precipitation hardened stainless steels are prized for their excellent strength-to-weight ratio. Additionally, they are able to be heat hardened like martensitic stainless steel and offer corrosion resistance similar to austenitic stainless steel.

13-8 Stainless Steel

13-8 is a low carbon stainless steel with high tensile strength and corrosion resistance. It is frequently found in airplane components and nuclear equipment.

15-5 Stainless Steel

15-5 has exceptional corrosion resistance and durability. It is often used in the aerospace, chemical, food processing, and general metalworking industries.

17-4 / 17-4PH Stainless Steel

17-4PH stainless steel contains higher quantities of chromium and copper. It is exceptionally strong and corrosion resistant. Its uses include offshore oil and gas and nuclear waste processing applications. It can also be found in airplane and automotive components.

17-4 stainless steel is similar to 17-4PH, but only undergoes a single heat treatment process during its manufacture. As such, it is softer but is generally used in the same applications.

Stainless Steel for Your Business Needs

Stainless steel exhibits several advantageous qualities, including excellent:

- Corrosion resistance

- Fire and heat resistance

- Impact resistance

- Strength-to-weight ratio

- Manufacturability

- Cleanability

These characteristics, in combination with generally low cost, superior aesthetic appearance, and greater sustainability, have led to stainless steel becoming one of the most commonly used construction materials across a diverse set of industries.

At Bergsen, we are committed to producing the best quality stainless steel for all industries. If you need stainless steel for your next project, contact us or request a quote today.